Sunward SWDH102S – a proven top hammer drilling rig with an install base of more than 60 units in the Middle East

PDF Catalog download SWDH102S

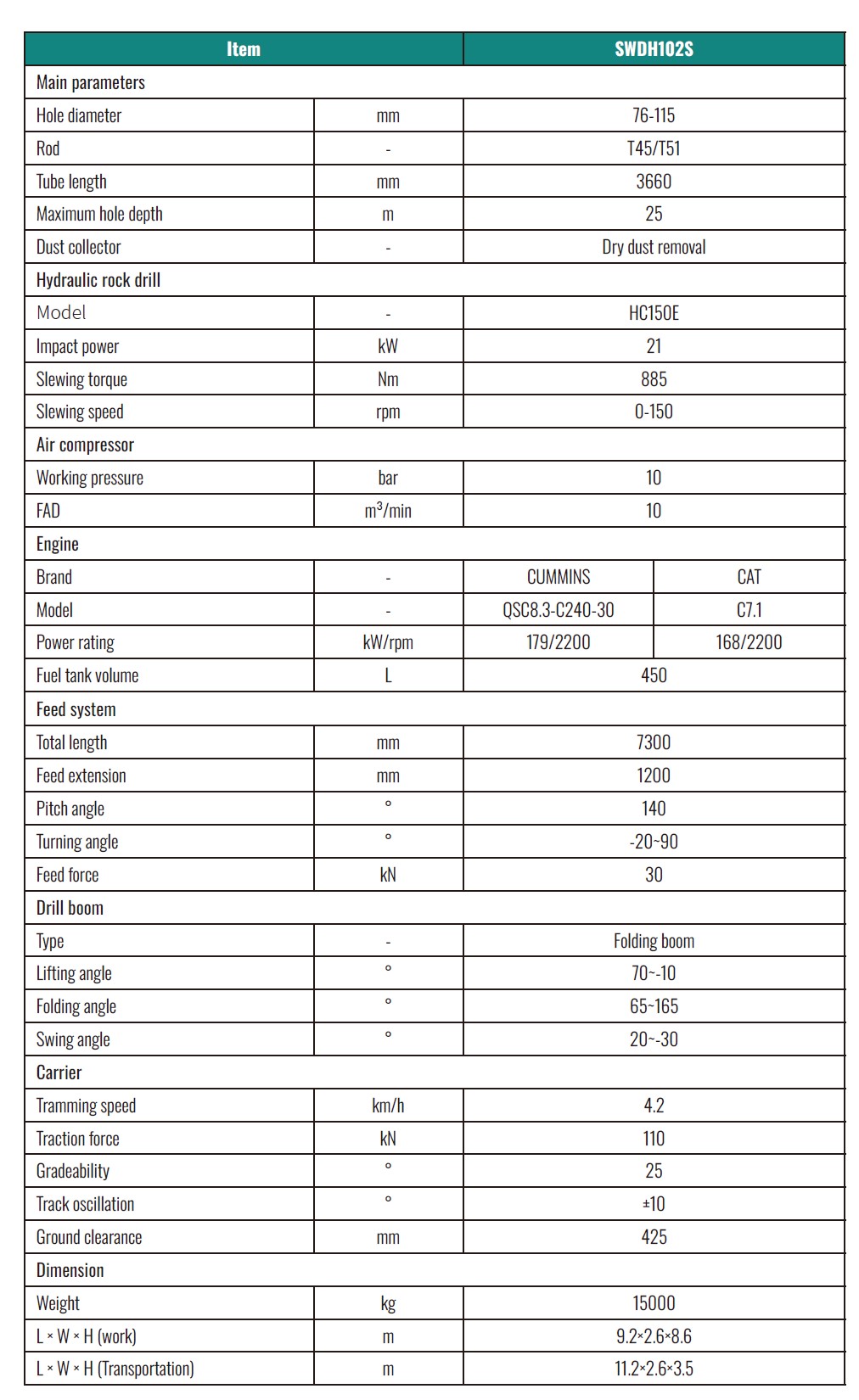

Overall specification:

| Item | SWDH102S | ||||

| Main parameters | |||||

| Hole diameter | mm | 76-115 | |||

| Rod | – | T45/T51 | |||

| Tube length | mm | 3660 | |||

| Maximum hole depth | m | 25 | |||

| Dust collector | – | Dry dust removal | |||

| Hydraulic rock drill | |||||

| Model | – | HC150E | |||

| Impact power | kW | 21 | |||

| Slewing torque | Nm | 885 | |||

| Slewing speed | rpm | 0-150 | |||

| Air compressor | |||||

| Working pressure | bar | 10 | |||

| FAD | m³/min | 10 | |||

| Engine | |||||

| Brand | – | CUMMINS | CAT | ||

| Model | – | QSC8.3-C240-30 | C7.1 | ||

| Power rating | kW/rpm | 179/2200 | 168/2200 | ||

| Fuel tank volume | L | 450 | |||

| Feed system | |||||

| Total length | mm | 7300 | |||

| Feed extension | mm | 1200 | |||

| Pitch angle | ° | 140 | |||

| Turning angle | ° | -20~90 | |||

| Feed force | kN | 30 | |||

| Drill boom | |||||

| Type | – | Folding boom | |||

| Lifting angle | ° | 70~-10 | |||

| Folding angle | ° | 65~165 | |||

| Swing angle | ° | 20~-30 | |||

| Carrier | |||||

| Tramming speed | km/h | 4.2 | |||

| Traction force | kN | 110 | |||

| Gradeability | ° | 25 | |||

| Track oscillation | ° | ±10 | |||

| Ground clearance | mm | 425 | |||

| Dimension | |||||

| Weight | kg | 15000 | |||

| L × W × H (work) | m | 9.2×2.6×8.6 | |||

| L × W × H (Transportation) | m | 11.2×2.6×3.5 | |||

Contact our engineering team to discuss your requirements in more details.

A blasthole drilling rig is a specialized piece of equipment used primarily in mining and construction industries to drill holes for explosives. These rigs are designed to create blastholes of varying depths and diameters for tasks such as blasting rock, excavating ore, or preparing the ground for construction projects like foundations or pipelines.

Key features of blasthole drilling rigs include:

- Powerful Drilling Mechanism: Blasthole rigs are equipped with powerful drilling mechanisms capable of penetrating various rock formations efficiently.

- Large Diameter Capacity: They can drill holes of significant diameter to accommodate the explosives required for blasting operations.

- Sturdy Construction: Blasthole drilling rigs are built to withstand harsh operating conditions in mining and construction sites.

- Mobility: Depending on the scale of the operation, blasthole rigs may be mounted on tracks, wheels, or trailers for mobility between drilling locations.

- Safety Features: These rigs incorporate safety features to protect operators and ensure compliance with industry regulations.

- Efficiency and Productivity: Designed for high productivity, blasthole drilling rigs are equipped with features to minimize downtime and optimize drilling performance.

Blasthole drilling rigs play a crucial role in the extraction of minerals, the development of infrastructure, and various earthmoving applications where precise drilling is essential for efficient operations.